Refractory Gunning mix:

Physical mixtures of refractory raw materials and a series of additives are called refractory soils and are divided into several categories in terms of raw materials or dryness and wetness, and are usually used by spraying with a device and vibrating. If this mixture is consumed by spraying, they are called refractory masses.

The physical mixture of refractory raw materials and additives that are designed to perform refractory by gunning method so that they have hydration properties are called refractory concrete in the market, but they are fundamentally different from ordinary concrete, and sometimes up to 10-15 types of materials. Make up different. Like ordinary sprays, low cement, very low cement.

The structure of refractory masses

Refractory masses include siliceous soils, spinel soils, additives, and lubricants, and are used to refract large furnaces, roofs, and high furnace walls. The majority of masses are based on calcium aluminate (CAC) cements. The hydration of cement is rapid. Relative humidity and the amount of SiO2 / CaO are very important factors in measuring the amount of viscosity of the liquid phase, which will have a great effect on the strength and refractory flexural strength.

Application of refractory masses

Refractory Gunning mix produced by Amol Carborundom Company has very significant properties compared to ordinary objects, including the following:

- Ability to design specifically for each customer and each equipment according to customer requests

- Easy and fast installation, especially in Gonning masses and Self-Flow masses (without the need for vibration)

- Unique abrasion resistance; Radiation, creep corrosion penetration, and slow melting including Sic, chromite, and…

- Flexibility in density and production of advanced insulation materials, including Low Iron and Chamotte, Perlite, and Babyl Alumina light masses

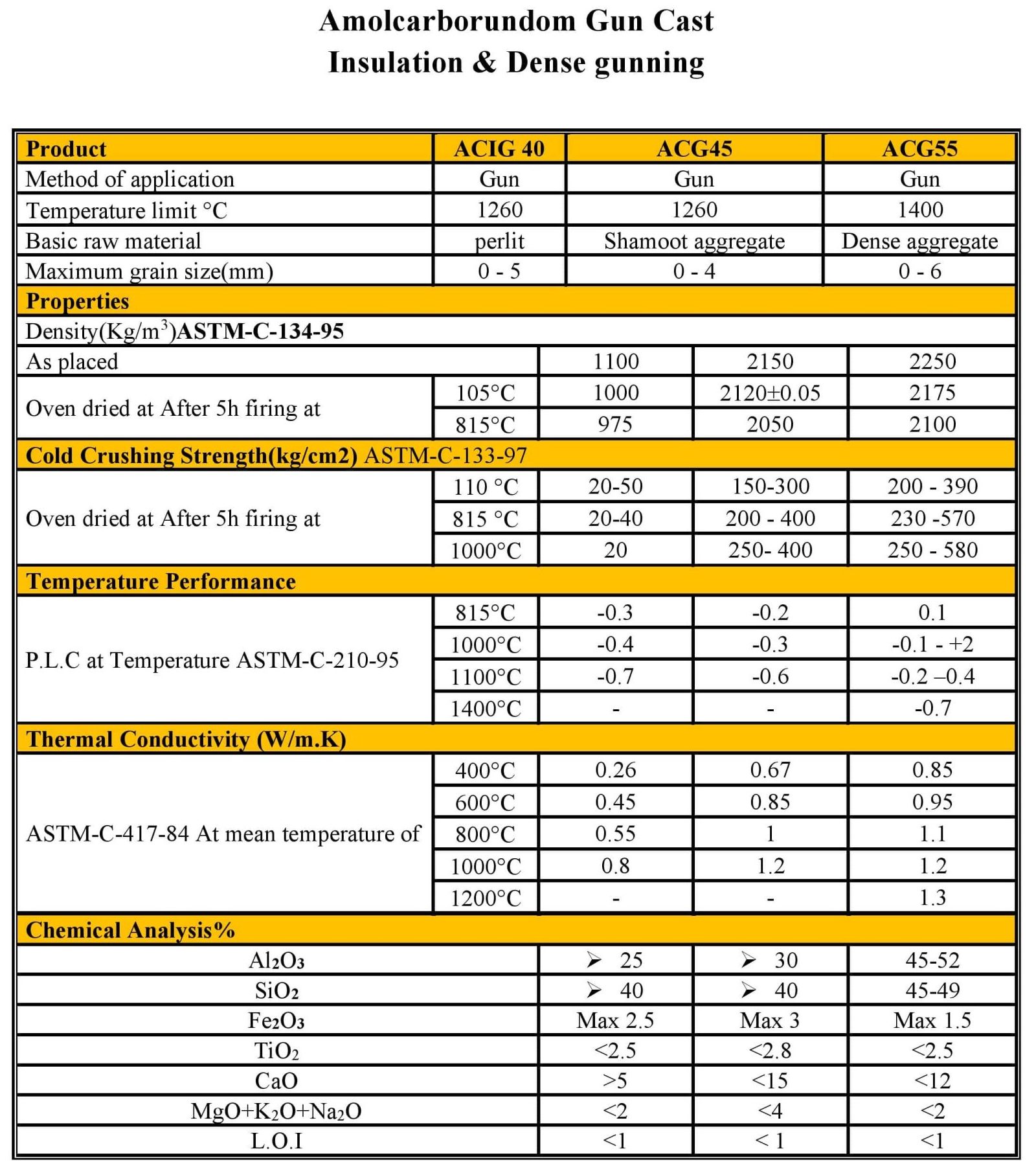

Technical Specifications

How to perform: Shotcreting

Engineers generally have relatively good information about the effect of fire on medium-strength concrete (meaning concrete up to 50 MPa). However, very little information is available on high-strength concrete and high-performance HPC concrete and the impact of fire on this concrete. As a rule, high-performance concretes in extreme heat and heat shocks are more sensitive than conventional NSC concretes due to their lower porosity coefficient, smaller pores, and vapor pressure. When the pressure inside the pores increases, tensile stress is produced in the concrete, and when this stress exceeds the allowable limit, explosive spalling of concrete begins. The part of the hot concrete surface that is strongly pushed out causes more concrete surfaces to be exposed to fire. This process continues until eventually the armature system is exposed and the fire directly affects them. The rapid expansion of some medium-weight aggregates and the reduction of space intensifies this phenomenon and helps to disintegrate and burst a layer of concrete. Undoubtedly, due to the type of concreting and shotcrete properties, this system is in the category of high-performance high-strength concretes and as a result is at risk of fire. This paper discusses the use of advanced calcium aluminate technology with stainless steel fibers and synthetic micro-polypropylene fibers to strengthen concrete structures and modify shotcrete properties for use in thermal shocks and high-temperature heavy industries.

See also: Heavy refractory masses

Types of shotcrete

Shotcrete is a mortar or concrete that is sprayed on the desired surface with high pressure and speed, which is divided into two types wet shotcrete (Wet Mix shotcrete) and dry mix (Dry Mix shotcrete ).) Known. In shotcrete with dry DMS mixture, materials including sand and cement are directed into the transfer pipe by shotcrete pump and transferred to the mortar sprayer (Nozzel), which is offered in the materials market as shotcrete powder. The required water in this case is added to the material as it leaves the nozzle, due to the very high speed of the material leaving the nozzle, this operation is done in a fraction of a second, in which case water may not reach some grains of cement. As a result, these grains are not hydrated. For this reason, the DMS method is used only in stabilization operations before tunnel lining and coating and repair works with a thickness of less than 10 cm. However, in the WMS method, a more shotcrete mixture with a ready-mixed concrete mixture is poured into the shotcrete pump and after passing through the transfer pipe, it reaches the nozzle and from there it is sprayed to the surface under the work with the help of compressor air pressure. Can be used when the compressive strength is desired. On the other hand, in this method, it is possible to execute concrete with a thickness of 50 cm for the wall and 20 cm for the ceiling in one step.