Injectable refractory paste

Injection refractory paste is a family of fibrous pastes that is used in the repair of hot spots of furnaces. Turns.

Repair hotspots using refractory paste

Today, due to the increasing expansion of industries, the use of industrial furnaces has grown significantly. These furnaces are considered as a very important sector in various industries such as steel, oil, gas and petrochemicals. If the refractory materials are not selected properly and also the refractory work is not performed properly, the furnaces will suffer from hot spots (HOT SPOT). Hot spots can further damage the refractory layers, damaging the furnace metal structure. This leads to shutdown outside the furnace schedule and the need for overhaul of the furnace, which leads to high costs and damage due to reduced production.

Features of injectable refractory paste

The fibrous nature of this injectable refractory paste leads to the formation of a layer with a coefficient of thermal expansion and low thermal conductivity and high shock absorption. On the other hand, the use of suitable binders causes proper strength after installation and drying.

Application of injection refractory paste

One of the most important applications of this material is hot repairs while the furnace is on. In this way, hot spots can be repaired and fixed online without turning off the oven.

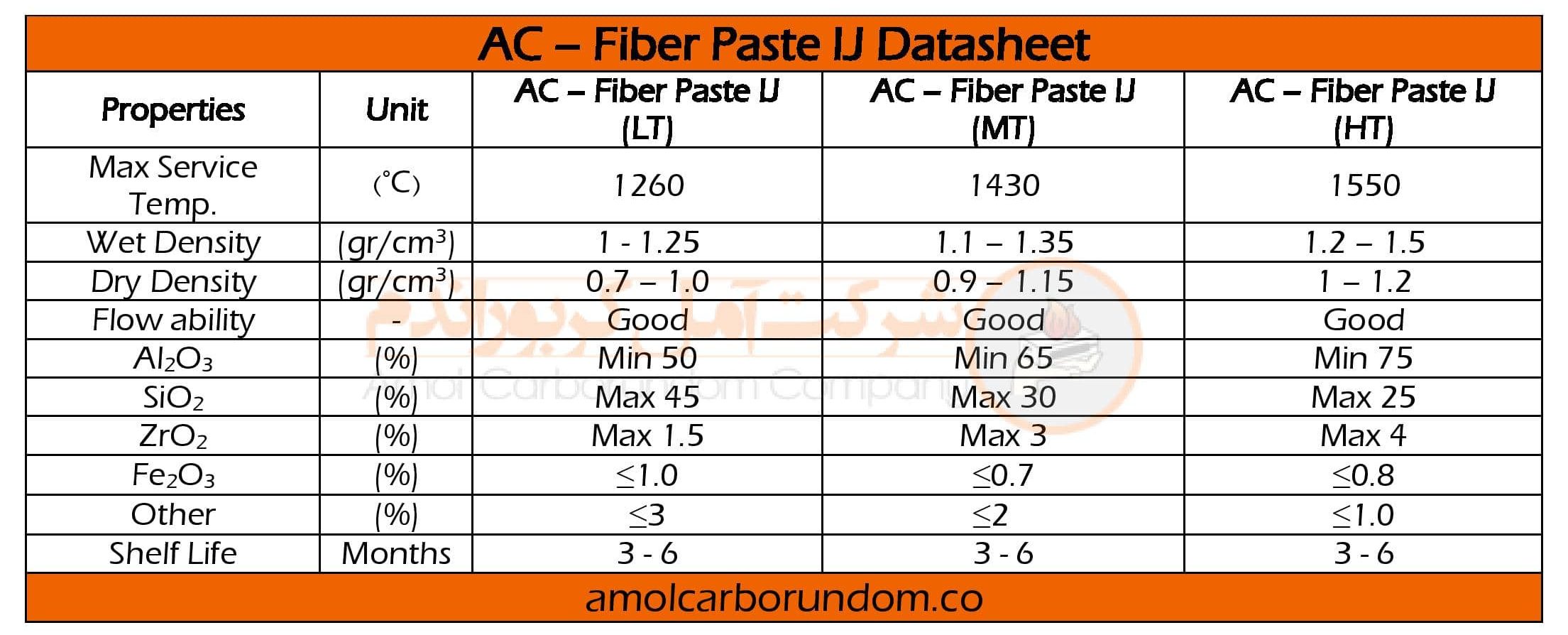

Technical specifications of the product

The following table shows the technical specifications of injectable refractory paste with the code AC-Fiber Paste IJ.